High Strength (S) glass fiber series products

Compared with E glass fiber,they exhibit 30%~40% higher tensile strength, 16%~20% higher modulus of elasticity, 10 folds higher fatigue resistance, 100°C~150°C higher temperature endure, also they have excellent impact resistance because of high elongation to break, high ageing and corrosion resistance, quick resin wet-out properties.

Properties

| Items | S2 | S4 | S6 |

|---|---|---|---|

| Virgin fiber tensile strentgh (MPa) | 4200 | 4600 | 4800 |

| Strand tensile strentgh (MPa) | 3000~3400 | 3200~3600 | 3600~4000 |

| Modulus of elasticity (GPa) | 87~91 | 90~94 | 92~96 |

| Elongation at break (%) | 5.3 | 5.3 | 5.7 |

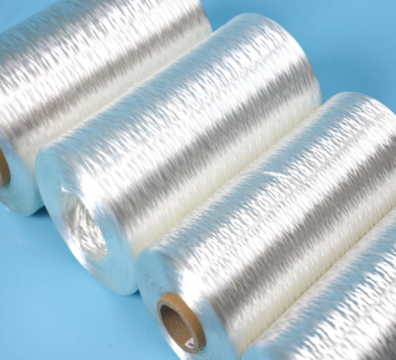

Yarns

S glass yarns are applied to hybrid, winding and other progresses.

Hybrided with aramid and UHMWPE fibers to make cutproof gloves, which has the advantages of high strength, soft, cut prove.

| Product designation | Tex | Twist (t/m) | Breaking strength (N) |

|---|---|---|---|

| SC8-12 X 1 | 12 | 55 | >7.2 |

| SC8-24 X 1 | 24 | 55 | >14.4 |

| SC8-24 X 1 X 2 | 48 | 55 | >28.8 |

| SC8-24 X 1 X 3 | 72 | 55 | >43.2 |

| SC8-28 X 1 X 4 | 112 | 100 | >67.2 |

| SC8-33 X 1 X 2 | 66 | 55 | >39.6 |

| SC9-66 X 1 | 66 | 55 | >39.6 |

★ Customized according to needs.

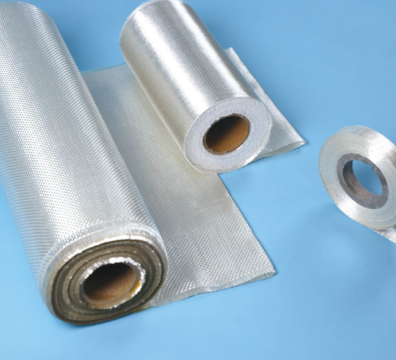

Fabrics

Fabrics are applied to prepreg, laminating, vacuum perfusing and other progresses.

Fabrics are made of direct-sized yarns which can be compatible with epoxy or vinyl eater without heat-cleaning process.

They are ideal reinforced materials for aerospace, marine, arment due to their higher tensile strength and higher modulus compared with E-glass fabrics.

The weaving patterns go to plain, twill, stain etc. The thickness ranges from 0.06mm~0.8mm.

| Product designation | Thickness (mm) | Count(ends/cm) Warp X Weft | Breaking strength(N/25mm) Warp X Weft | Weight (g/cm²) | Compatiable resin | Weaving pattern |

|---|---|---|---|---|---|---|

| SW60A-100a | 0.06 | 12 X 12 | 500 X 500 | 60 | Epoxy | Plain |

| SW80B-90b | 0.08 | 16 X 16 | 500 X 500 | 80 | Vinyl | Twill |

| SW80B-90a | 0.08 | 16 X 16 | 500 X 500 | 80 | Epoxy | Twill |

| SW110A-100a | 0.10 | 20 X 20 | 550 X 550 | 100 | Epoxy | Plain |

| SW110C-100a | 0.11 | 22 X 22 | 600 X 600 | 110 | Epoxy | 4HS |

| SW140B-90a | 0.14 | 14 X 14 | 900 X 900 | 140 | Epoxy | Twill |

| SW160C-100a | 0.16 | 18 X 12 | 2000 X 400 | 160 | Epoxy | 4HS |

| SW180D-100a | 0.18 | 18 X 18 | 1200 X 1200 | 180 | Epoxy | 5HS |

| SW210B-100a | 0.21 | 16 X 12 | 1600 X 1350 | 200 | Epoxy | Twill |

| SW210A-92a | 0.21 | 16 X 12 | 1600 X 1350 | 200 | Epoxy | Plain |

| SW220B-90a | 0.22 | 18 X 14 | 1900 X 1600 | 240 | Epoxy | Twill |

| SW220B-90b | 0.21 | 18 X 14 | 1900 X 1600 | 240 | Vinyl | Twill |

| SW220C-90a | 0.22 | 18 X 14 | 2000 X 1600 | 240 | Epoxy | 4HS |

| SW220D-90a | 0.22 | 18 X 14 | 2000 X 1600 | 240 | Epoxy | 5HS |

| SW220C-100b | 0.21 | 18 X 14 | 1900 X 1600 | 240 | Vinyl | 4HS |

| SW280F-100a | 0.25 | 20 X 18 | 2000 X 1700 | 280 | Epoxy | 8HS |

| SW600B-105a | 0.60 | 14 X 11 | 3500 X 3000 | 600 | Epoxy | Twill |

★ Customized according to needs.

Roving

S glass roving yarns are applied to winding, prepreg and other progress.

Special sized roving yarns made to meet quick wet-out and easy spread-out requirements, they are ideal materials for helicopter blade, leisure goods.

| Tex | 240 | 400 | 480 | 600 | 660 | 735 | 800 | 1200 | 1980 | 2400 |

|---|---|---|---|---|---|---|---|---|---|---|

| Yield | 2067 | 1250 | 1034 | 827 | 750 | 675 | 606 | 423 | 250 | 206 |

★ Customized according to needs.

Roving Fabrics

Roving Fabrics are applied to laminating, vacuum perfusing and other progresses.

S glass roving fabrics by heat-set, weaving or stitching process can be fabricated to unidirectional fabric, woven roving fabric and stitched fabric.

Composite properties can be significantly improved due to their higher tensile strength and higher modulus compared with E-glass fabrics.

Unidirectional fabrics

| Product designation | Warp tex | Weft tex | Count (ends/cm) | Weight (g/m²) | Thickness |

|---|---|---|---|---|---|

| SWU414 | 600 | Heat set yarn | W6.1 F1.6 | 414 | 0.34 |

| SWU173 | 400 | W3.9 F1.6 | 173 | 0.14 |

Woven fabrics

| S | Warp and Weft | Count (ends/cm) | Weight (g/m²) | Breaking strength (N/25mm) |

|---|---|---|---|---|

| SWR400 | 660 | W3.0 F3.0 | 400 | W2700 F2700 |

| SWR800 | 1980 | W2.0 F2.0 | 810 | W4950 F4950 |

Stitched fabrics

| Product designation | 0° | 90° | -45° | +45° | Weight (g/m²) |

|---|---|---|---|---|---|

| BIAX350 | 175 | 175 | – | – | 350 |

| BIAX600 | – | – | 300 | 300 | 600 |

★ Customized according to needs.

Chopped strand

S glass yarn can be cut to 3, 6, 9, 12mm and other length chopped strands.

Application cases